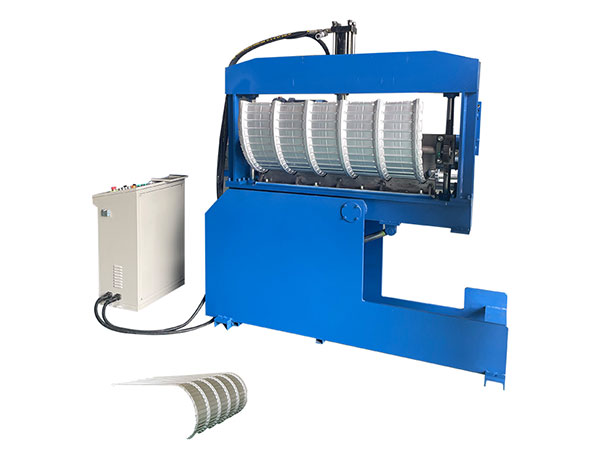

Crimp Curving Machine (Crimp Roofing Sheet)

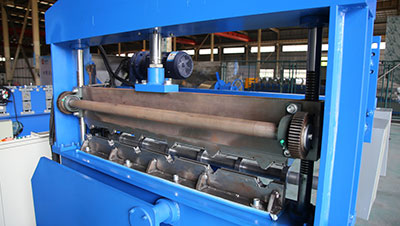

A crimp curving machine is an industrial tool designed to curve or crimp metal sheets, enhancing their strength, durability, and visual appeal. It operates by passing metal sheets through rollers or bending dies to shape the material into the desired corrugated pattern.

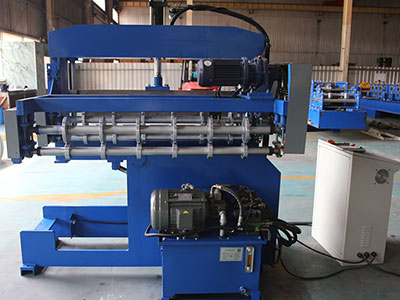

| Model Number | YX25-205-1025 |

| Dimension | 1500*1500*1400mm |

| Weight | 800kg |

| Motor Power | 5.5kW |

| Hydraulic Power | 1.5kW |

| Voltage | 400V/50Hz/3ph |

| Bending Width | 1025mm |

| Thickness of Crimp Roofing Sheet | 0.4-0.8mm |

| Mini. Bending Radius | 1.5m |

| Material of Roof Panel | Color-coated steel or galvanized steel |

- Enhanced Aesthetics: One of the most noticeable benefits of curved metal roofing is its striking visual appeal. With a curving machine, you can create smooth curves and unique shapes, textures, and angles, making any building or residence stand out.

- Maximized Space: Arched roofs created by this equipment allow property owners to optimize available space without the need for steep slopes. This design feature helps maximize every square inch of a home or business, offering a practical and efficient roofing solution.

- Increased Roof Durability and Lifespan: Similar to traditional metal roofing, curved metal roofs are renowned for their longevity and durability, often lasting between 40 to 70 years. The inherent strength of metal ensures high performance, and curved metal roofs are no exception, offering long-lasting protection and reliability.

Get in Touch

Xinhonghua has been specialized in engineering, design and manufacture of roll forming machinery and a total solution provider of steel framing technology. Since 2004, Xinhonghua has developed a durable line of roll forming equipment and has earned a reputation for high quality and reliability worldwide.

Whether you’re starting a new metal roofing business, expanding production, or looking to steel frames, we look forward to providing the service and guidance you need to launch your cold formed steel construction projects. Our company provided rollforming machines to hundreds of customers in more than 40 countries and regions, including Southeast Asia, Europe, Africa, Australia, etc.

We believe our roll forming machines set the highest benchmarks for productivity, reliability, and safety in the manufacture of structural steel framing products. Xinhonghua will be with you every step of the way to ensure your success!