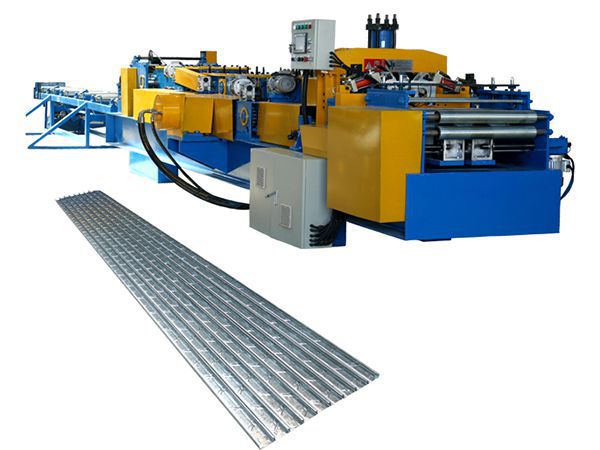

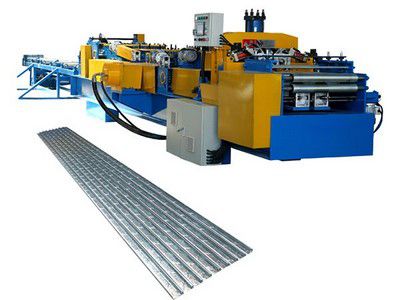

C60-250 C Purlin Roll Forming Machine (Automatic Adjustable)

C60-250 C purlin roll forming machine allows for the automatic width adjustment for profiling purlins with a width from 60mm to 250mm. The changeover time is under 1 minute. A thickness 1.0mm-3.0mm can be used as raw materials.

- Make different C purlin sizes without changing rollers or spacers

- Width adjustment within 60-250mm and changeover is within 1 minute

- Pre-cutting system device (optional post-cutter), without changing cutter for different sizes

- Optional punch hole at any position of purlin web and flange

| Model | C60-250 |

| Dimension | 7800*1600*1600mm |

| Hydraulic Motor | 18.5kW |

| Motor Power for adjusting C size | 0.37kW*2+0.75kW |

| Motor Power for guiding | 0.18kW*2 |

| Motor Power for adjusting punching hole | 0.18kW*2 |

| Forming Steps | 13Steps+3steps for reshaping |

| Forming Speed | 8m/min,16m/min, 25m/min |

| Voltage | 380V/50HZ/3Phase |

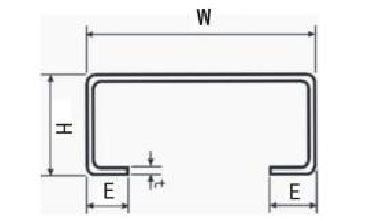

| Effective Width | 60-250mm |

| Material Width | 122-402mm |

| Flange Height of Purlin | 30-75mm |

| Material Thickness | 1.0-3.0mm |

| Control System | PLC computer control |

| Rollers | Made using Gcr15 steel with heat treatment, hard chrome plating on the surface of rollers |

| Material for Shaft | 40Cr steel |

| Material for Puncher | Cr12Mov |

| Material for Cutter | Cr12Mov |

-

-

Rollers are manufactured from high quality bearing steel GCr15 and are processed with CNC lathes and heat treatment. Hard-chrome plating or black oxide coating is optional. It includes a feeding material guide roller, and body frame is welded 400# H type steel.

- Main Purlin Forming Machine

- 3 Tons Manual Uncoiler

- Automatic Guide Device

- Automatic Reshaping Device

- PLC Computer Controlling System with Touch Screen (Brand: Schneider)

- Hydraulic Motor System

- Pre-punching Holes Device (the buyer decide the size of punching holes)

- Pre-cutting Device (Available to add post-cutter)

- Run Out Table

Get in Touch

Xinhonghua has been specialized in engineering, design and manufacture of roll forming machinery and a total solution provider of steel framing technology. Since 2004, Xinhonghua has developed a durable line of roll forming equipment and has earned a reputation for high quality and reliability worldwide.

Whether you’re starting a new metal roofing business, expanding production, or looking to steel frames, we look forward to providing the service and guidance you need to launch your cold formed steel construction projects. Our company provided rollforming machines to hundreds of customers in more than 40 countries and regions, including Southeast Asia, Europe, Africa, Australia, etc.

We believe our roll forming machines set the highest benchmarks for productivity, reliability, and safety in the manufacture of structural steel framing products. Xinhonghua will be with you every step of the way to ensure your success!