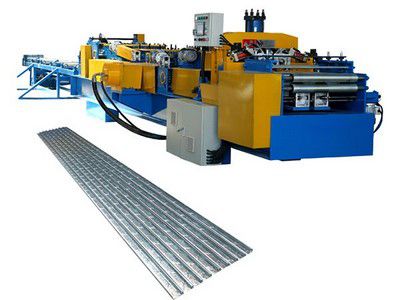

Hat Channel Roll Forming Machine

The hat channel roll forming machine is used to manufacture hat-shaped channels, commonly applied in construction and other industries. The channel’s shape typically resembles the Greek letter Omega (Ω), giving it its name. These channels serve as structural supports or framing components in various applications, including walls, ceilings, and roofing systems.

- Lightweight: Due to its thin-walled structure, the hat channel is relatively lightweight compared to solid beams or other framing materials, making it easier to handle and install.

- Excellent Durability: Hat channels are known for their durability and resistance to bending or warping under load, making them ideal for applications where structural stability is crucial.

- Customizable Length Options: Hat channels are available in various lengths and can be cut on-site to the required dimensions or customized to meet specific project needs.

- Flexible Installation Options: Hat channels can be attached to walls, ceilings, or other surfaces using screws, bolts, or other fasteners. They also serve as mounting surfaces for various fixtures and equipment.

- Sound and Thermal Insulation: Hat channels are sometimes used as part of soundproofing or thermal insulation systems. They can be combined with insulation materials to create an air gap that enhances sound and thermal performance.

| Item | YX38-68 galvanized steel hat channel roll forming machine |

| Dimension | 5500*1100*1400mm |

| Weight | 2000kg |

| Hydraulic Power | 1.5kW |

| Motor Power | 7.5kW |

| Voltage | 380V / 3 Phase / 60Hz |

| Forming Steps | 14 |

| Forming Speed | 0-20m/min |

| Purlin Height | 38mm |

| Effective Width | 68mm |

| Thickness | 1.2-1.6mm (Material: Q235GI) |

| Cutting Tolerance | ±2mm |

| Roller Material | High-quality 45# forged steel, polished, and hard chromium plated |

| Raw Material | Galvanized sheet |

-

-

Material Feeding

The process starts by feeding a coil of sheet metal into the machine. The coil can be made of different materials such as steel, aluminum, or galvanized steel, depending on the application and the desired characteristics of the hat channels.

-

-

Roll Forming

The machine utilizes a series of precisely designed rollers and dies to progressively shape the flat sheet metal into the desired hat channel profile. Each set of rollers along the machine’s length performs specific bending and forming actions. This gradual process ensures accurate and consistent shaping of the hat channels with uniform dimensions.

Get in Touch

Xinhonghua has been specialized in engineering, design and manufacture of roll forming machinery and a total solution provider of steel framing technology. Since 2004, Xinhonghua has developed a durable line of roll forming equipment and has earned a reputation for high quality and reliability worldwide.

Whether you’re starting a new metal roofing business, expanding production, or looking to steel frames, we look forward to providing the service and guidance you need to launch your cold formed steel construction projects. Our company provided rollforming machines to hundreds of customers in more than 40 countries and regions, including Southeast Asia, Europe, Africa, Australia, etc.

We believe our roll forming machines set the highest benchmarks for productivity, reliability, and safety in the manufacture of structural steel framing products. Xinhonghua will be with you every step of the way to ensure your success!