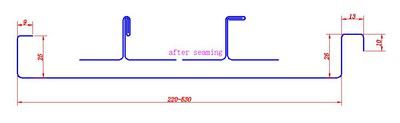

KLS25-220-530 Standing Seam Roofing Machine

KLS25-220-530 standing seam roofing machine is capable of profiling 0.7-1.0mm thick aluminum roof panel and 0.5-0.8mm thick steel roof panel. This machine can roll form both straight and tapered profiles. Schneider PLC control system is optional for easy operation. Small footprint is convenient for use on site.

| Model | KLS25-220-530 |

| Dimension | 1800*1200*1000mm |

| Motor Power | 1.5KW |

| Hydraulic Power | 0.75KW |

| Forming Steps | 6Steps |

| Forming Speed | 8-15m/min |

| Voltage | 380V/50HZ/3PH |

| Effective Width | 220-530mm |

| Material Width | 290-600mm |

| Height of Roofing | 25mm |

| Aluminum Thickness | 0.7-1.0mm |

| Steel Thickness | 0.5-0.8mm |

| Control System | PLC Control |

- Main forming machine for make straight and tapered roof

- 5 Tons Manual Uncoiler

- Auto Seamer

- Hand Seamer

- PLC computer controlling system with touch screen (Brand: Schneider)

- Hydraulic Forming Cutter

- Device for Making Tapered Standing Seam Roofing

- Run Out Table

- Operation Manual

Get in Touch

Xinhonghua has been specialized in engineering, design and manufacture of roll forming machinery and a total solution provider of steel framing technology. Since 2004, Xinhonghua has developed a durable line of roll forming equipment and has earned a reputation for high quality and reliability worldwide.

Whether you’re starting a new metal roofing business, expanding production, or looking to steel frames, we look forward to providing the service and guidance you need to launch your cold formed steel construction projects. Our company provided rollforming machines to hundreds of customers in more than 40 countries and regions, including Southeast Asia, Europe, Africa, Australia, etc.

We believe our roll forming machines set the highest benchmarks for productivity, reliability, and safety in the manufacture of structural steel framing products. Xinhonghua will be with you every step of the way to ensure your success!