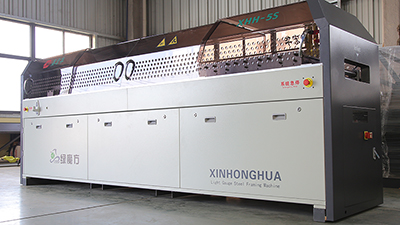

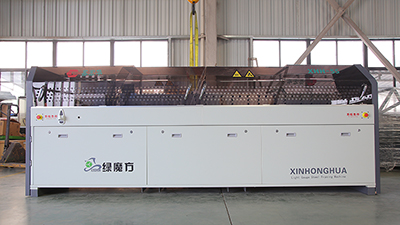

XHH-5S-C89 Light Gauge Steel Framing Machine

Steel Frame Roll Forming Machine

XHH-5S-C89 light gauge steel framing machine is used for the producing of steel studs and truss for light steel frame construction and prefabricated construction from 2 to 3 stories. Equipped with the latest technology Vertex Design Software, this steel frame rollformer allows for automatic production. This machine is designed to roll form 0.6 mm-1.2 mm thick and 174mm wide materials.

| Model | C89 |

| Dimension | 4200*800*1100mm |

| Main Servo Motor | 7.5kW |

| Hydraulic Motor | 7.5kW |

| Forming Steps | 9Steps |

| Forming Speed | 4-5tons/8hours |

| Voltage | 380V/50Hz/3Phase |

| Effective Width | 89mm |

| Material Width | 174mm |

| Flange Height | 38mm |

| Lip | 9mm |

| Material Thickness | 0.6-1.2mm |

| Tolerance for Cutting and Punching | ±0.5mm |

| Tolerance for Forming | ±0.75mm |

| Control System | IPC computer controlling system |

| Design Software | Vertex software |

| Rollers | Made using SKD-11 steel with heat treatment, hard chrome plating on the surface of rollers |

| Material for Shaft | SKD-11 |

| Material for Puncher | SKD-11 |

| Material for Cutter | SKD-11 |

- Main Forming Machine

- 3 Tons Electric Uncoiler

- Servo Motor System

- IPC Computer Controlling System (Lenovo Laptop)

- Production Software (1set)

- Design Software-Vertex, forever using license

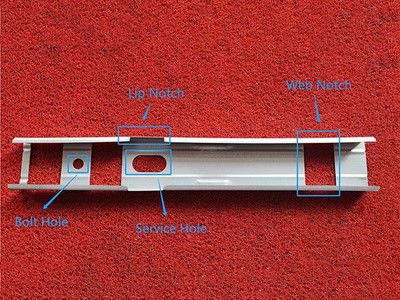

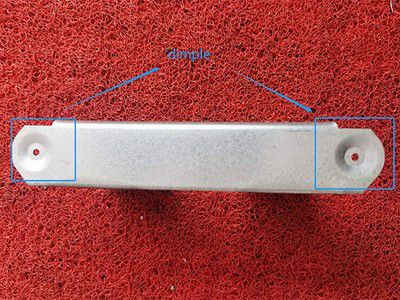

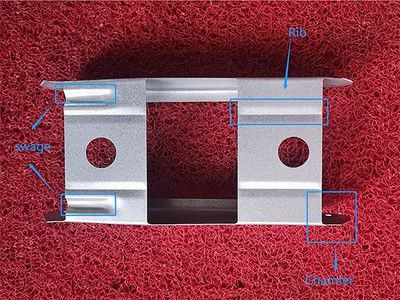

- Hydraulic Automatic Punching Device (Web/Lip Notch, Swage, Service Hole, Chamfer, Dimple, Bolt Hole)

- Hydraulic Post-cutting Device (Material:SKD-11)

- Automatic Printing Device

- Run Out Table (4m)

- Operation Manual

-

-

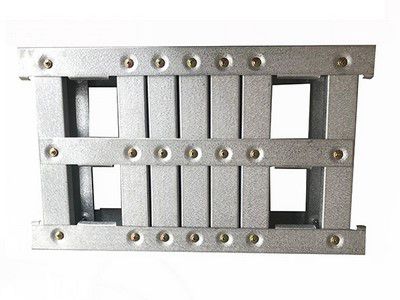

Post Punching Mould

XHH LGS Machine all with post punching and post cutting, which make more high precision performance on position & dimension

-

-

Seamless end cut connection

Seamless end-cut connection is a patent design of XHH LGS FORMER. The two ends of the vertical frame can seamlessly connect to the web of the bottom and top horizontal frames. So the weight of the house can be directly loaded and passed by the vertical frame, which makes the house safer.

-

-

Continuous web notch punching without extruding material

The strength of raw material will be greatly reduced when continuous web & lip notches are made, thus material in the pre-punching machine may be easily extruded and then cause machine jam during roll forming process. XHH LGS Machine with post punching system, which we can do more continuous web notch even in 0.55mm thin thickness without extruding material.

-

-

Lower material wasting

Short distance between punching & cutting die able to limit the start-up material waste length at 0.02m, and end material waste length within 1 meter.

-

-

Save Cost

XHH Machine steel strip width is: 170-174mm width, 10mm less than the most other machines in the market. For a 200sm house, the total frame is around 7000m,can save 439.6-659.4kg material

Material Thickness 0.8mm 1.0mm 1.2mm Material Saved Per House 439.6kg 549.5kg 659.4kg The length of each start-up waste of the XHH post-punching & cutting machine is about 1M; most machines on the market are pre-punching & post-cutting (other supplier), their waste material is about 8m on each start-up

Start-Up/Change Steel Coil 8.11-12.13 Kg 5 Steel Coils/Day 40.55-60.65 Kg Material Saved/Year 12.17-18.2 T

Get in Touch

Xinhonghua has been specialized in engineering, design and manufacture of roll forming machinery and a total solution provider of steel framing technology. Since 2004, Xinhonghua has developed a durable line of roll forming equipment and has earned a reputation for high quality and reliability worldwide.

Whether you’re starting a new metal roofing business, expanding production, or looking to steel frames, we look forward to providing the service and guidance you need to launch your cold formed steel construction projects. Our company provided rollforming machines to hundreds of customers in more than 40 countries and regions, including Southeast Asia, Europe, Africa, Australia, etc.

We believe our roll forming machines set the highest benchmarks for productivity, reliability, and safety in the manufacture of structural steel framing products. Xinhonghua will be with you every step of the way to ensure your success!